Gasket Plate Heat Exchangers

What is PHE

Plate Heat Exchangers have been used in all kinds of industries as compact heat exchangers with maximum efficiency.

The Plate Heat Exchanger is a heat transfer equipment consisting of a pack of heat transfer plates, compressed by frames and tightening bolts. Heat transfer plates are made by pressing thin sheets of corrosion-resistant metal such as stainless steel or titanium, setting them with seal gaskets and hanging and piling them on the guide bar. Then, plates are tightened with bolts between the fixed frame and the movable frame.

Here, there is a certain gap between the heat transfer plates that allows liquid to flow.

The liquid inlets and outlets are in the fixed frame or the movable frame.

Features and advantages

Our plate heat exchanger has excellent characteristics such as high-energy efficiency, compact size, easy maintenance, easy adjustment to capacity change, and relatively low capital investment.

Our wide range of sizes, plates, gasket materials, and add-ons allows you to flexibly and creatively design and configure according to the applications, from the simplest tasks to the most demanding performance and documentation requirements.

High Thermal Efficiency

The press-formed patterns provide a high heat transfer coefficient by a turbulence flow.

Lightweight and Smaller Footprint

Less weight and compact size can be realized by the thin heat transfer plates and the small holding volume.

These features provide simple installation work with low cost.

– Compressed thin heat transferring plates

– Limited fluid capacity

– Smaller heat transferring surface area

Quick Start-up

Smaller holding volume makes quick start-up of the process.

Limited fluid capacity per unit allows quick operation start up, and also possible to correspond to changes in operating conditions with high precision.

Easy maintenance

Simple Assembly and disassembly for inspection and maintenance by loosening the bolts and nuts.

Modular Construction and Design Flexibility

Flexibility to easily implement various thermal programs and future expansions/modifications.

Prevention of Liquid Inter-mixing

Gasket grooves protect it from direct contact with the liquid.

The double-seal gasket with drain avoids any mixing of the two liquids preventing performance deterioration in case of a gasket failure.

World Class of Plate Design

Arsopi Thermal + HISAKA

The forefront of plate design technology for special or difficult applications, expanding the use of regular plate and gasket plate heat exchangers.

Plates & Special Plates

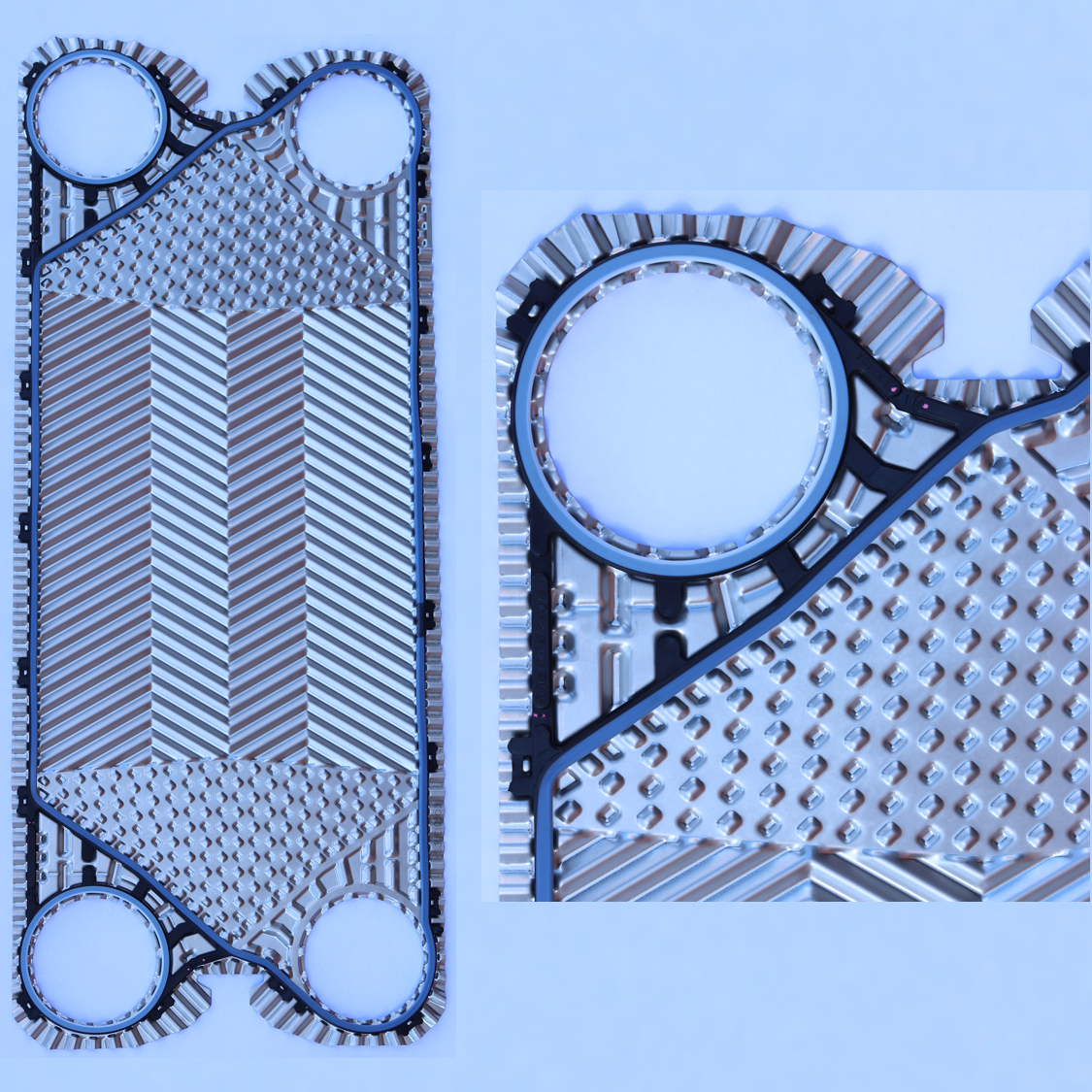

The plate pack is the active part of the heat exchanger where the heat exchange takes place.

Each heat transfer plate is a thin sheet of corrosion-resistant metal such as stainless steel or titanium.

The surface is corrugated to various patterns to increase its strength and surface area and the corrugation makes high turbulence which achieves a high heat transfer coefficient.

Portholes are formed in the plate's four corners.

The gasket is set into the groove around the plate edge to seal in the fluid.

Plate Element Types

Arsopi Thermal offers plates with different surface shapes so that you can choose the most suitable plate heat exchanger according to your application.

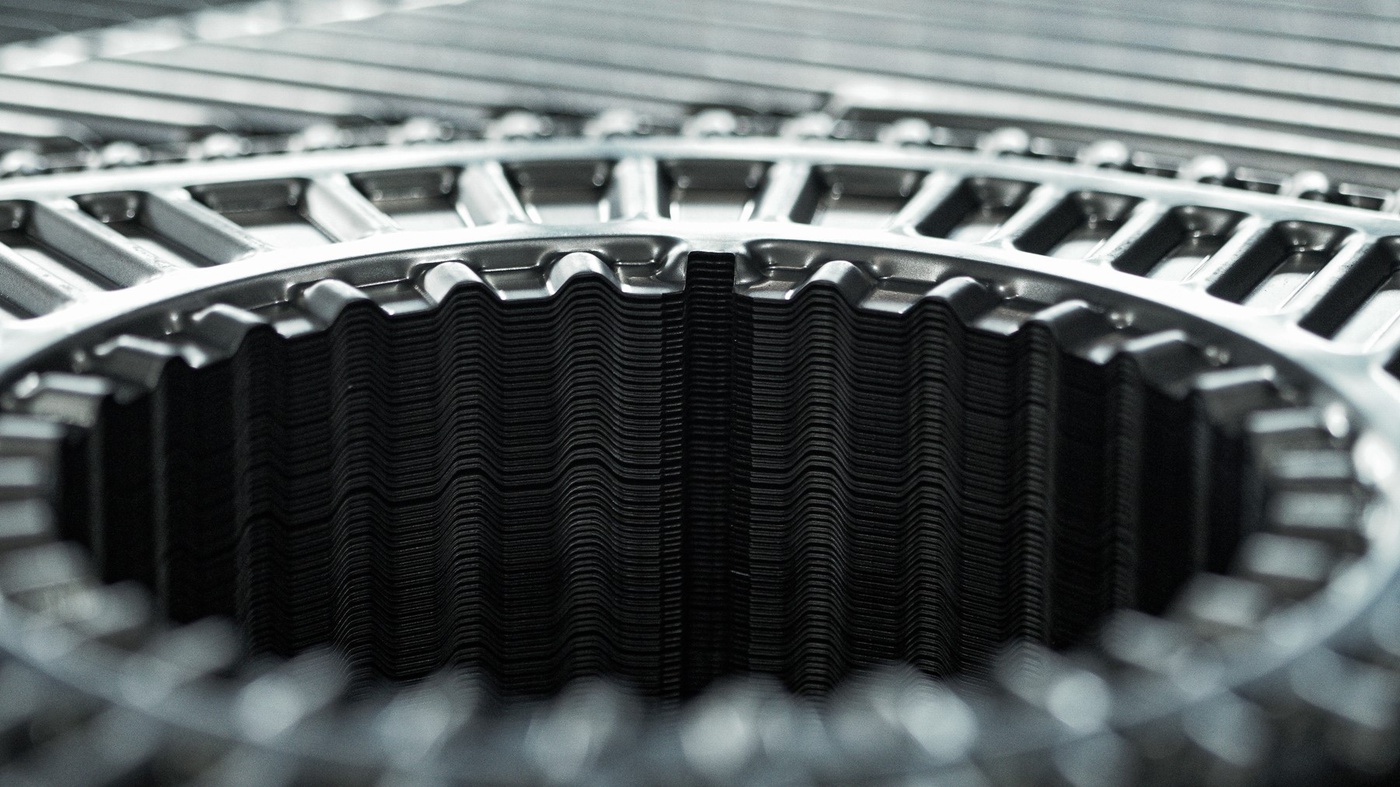

Wave Corrugated Pattern

The wave corrugated pattern is also known as the washboard pattern.

There are few points of metal contact between the plates, allowing liquids containing fibres and sludge to easily flow without clogging.

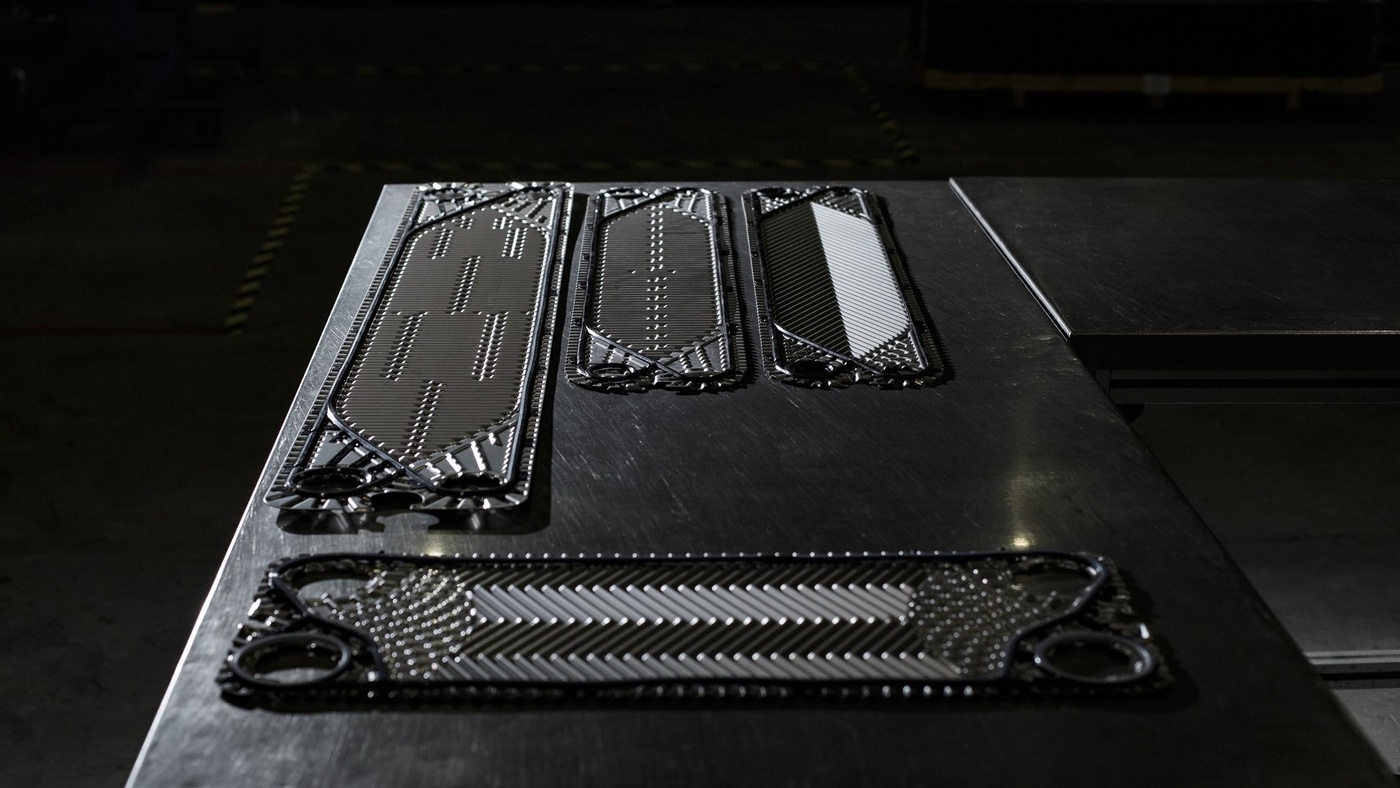

Herringbone Pattern

The “herringbone” pattern was named, as the V-shaped press grooves resemble the bones of a herring.

Pilling the V-shaped pressed plate and rotating it 180 degrees in an alternating pattern can create many contact points.

This ensures high-pressure resistance and the complicated flow path formed by the V-shaped press grooves delivers high heat transfer performance. Moreover, the thin plate reduces the heat transfer resistance, and all this results in a 3-5 times better heat transfer performance than the S&T heat exchanger.

Combining different types of herringbone can optimise this mixed arrangement and decrease the heat transfer area.

Thus, results in an optimal technical / economical solution.

Special Plates

Aside from the concept of an individual heat transfer plate, we also offer the following special plates with outstanding performance to meet more diverse and advanced requirements.

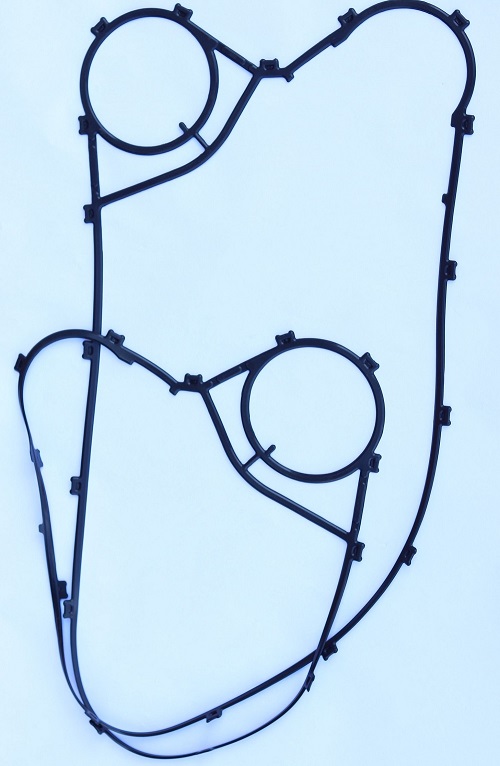

Gaskets & Special Gaskets

Gaskets used in plate heat exchangers need durability to withstand a wide range of liquid qualities and temperature / pressure conditions.

Our original gaskets are manufactured under very strict quality control with the highest material quality to support a wide variety of applications.

Combined with a careful gasket material selection, high performance and gasket durability can be expected.

Main material available are:

Material | Application | Temperature |

| NBR | Water, Brine, Oil application, Daily products, Food & Beverages applications | 130˚C |

| EPDM | Steam, Hot Water, Caustic Soda, Alcohol, Ammonia, Weak Acid & Alkaline solution, Daily products, Food & Beverages applications | 150˚C |

| EPDM-HT | Steam, Hot Water, Caustic Soda, Alcohol, Ammonia, Weak Acid & Alkaline solution | 180˚C |

| PTFE Encapsulated NBR/EPDM | Organic Chemicals, Solvent, Ultra Pure water, High chemical resistance | 150˚C |

| FKM (VITON) | Good chemical resistance towards concentrated acids, Oils, lubricants and fuels, Daily products, Food & Beverages applications | 175˚C |

| N-EPDM | High temperature, Aggressive media, Improved sealing performance | 180˚C |

Special Gasket

Accessories, Connections, Special Parts

Arsopi-Thermal flexible production is focus on customer’s needs and we can supply different solutions customized to our customer’s demands.

A variety of accessories are available:

- Condensate tray

- Metallic protection cover

- Insulation

- Standard and Customized connections

- Inlet filters

- Thermometers and manometers

- Different RAL Paint colours and procedures according customers´ requests

- Others upon request

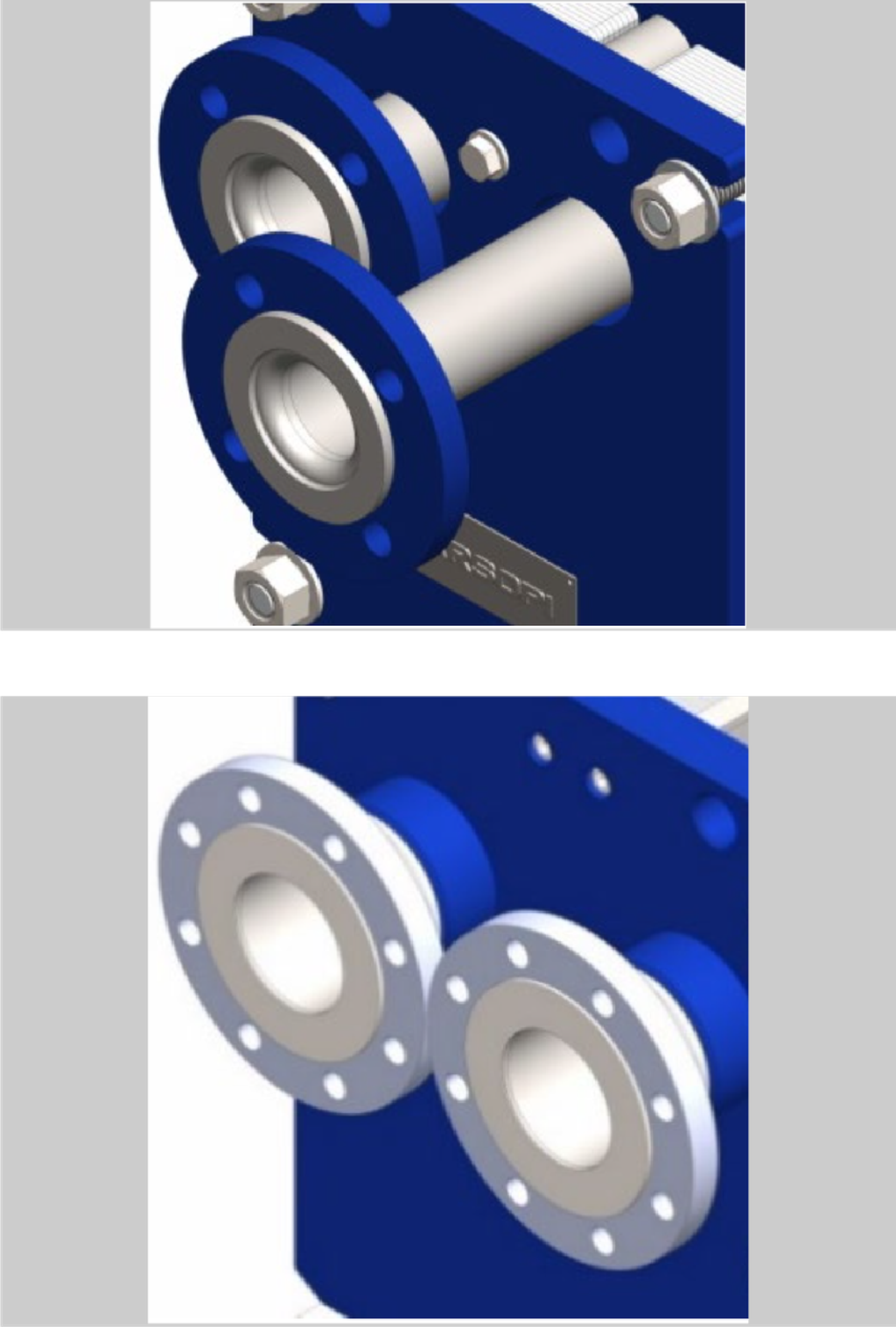

Connections

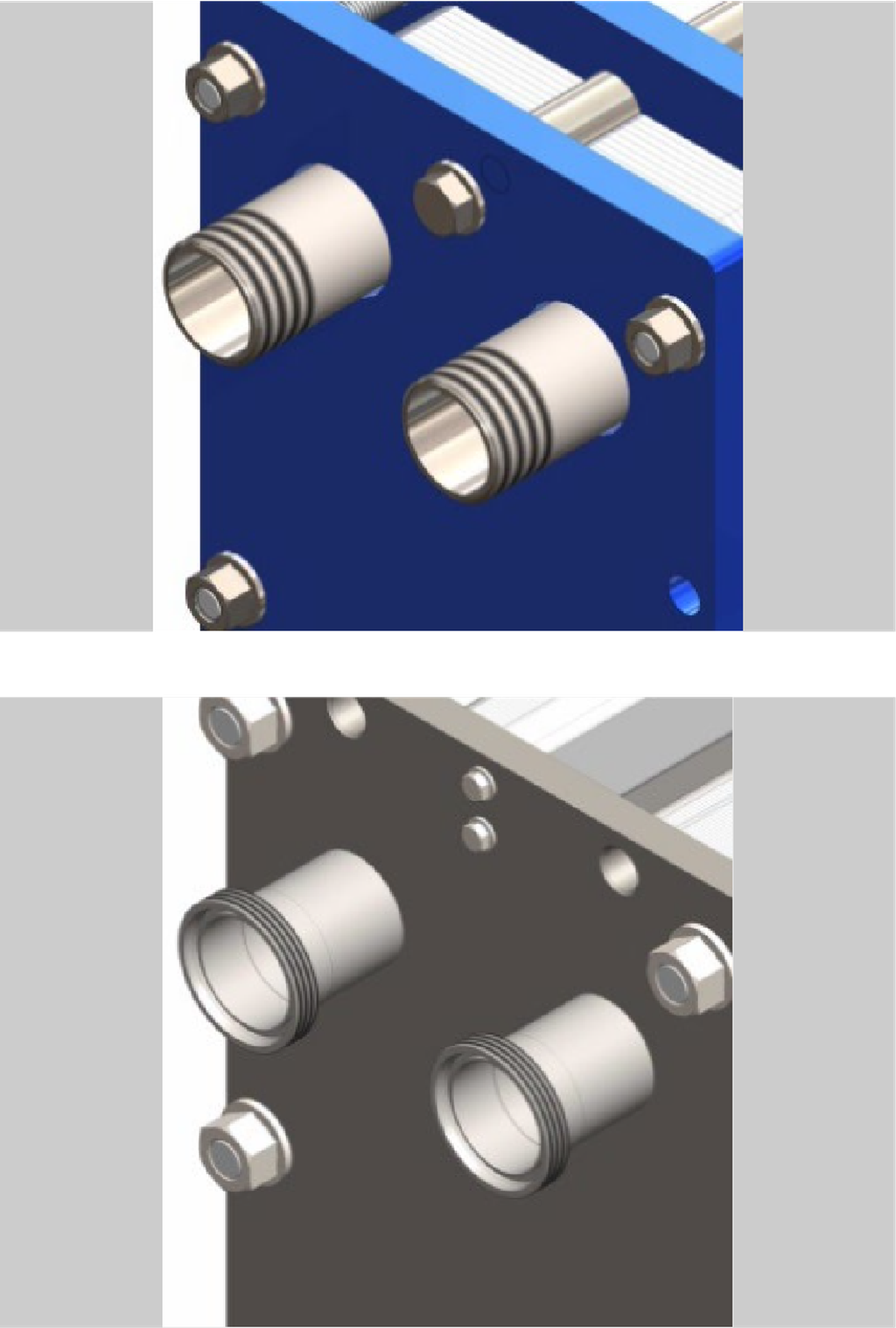

Threaded Port

Studded Port

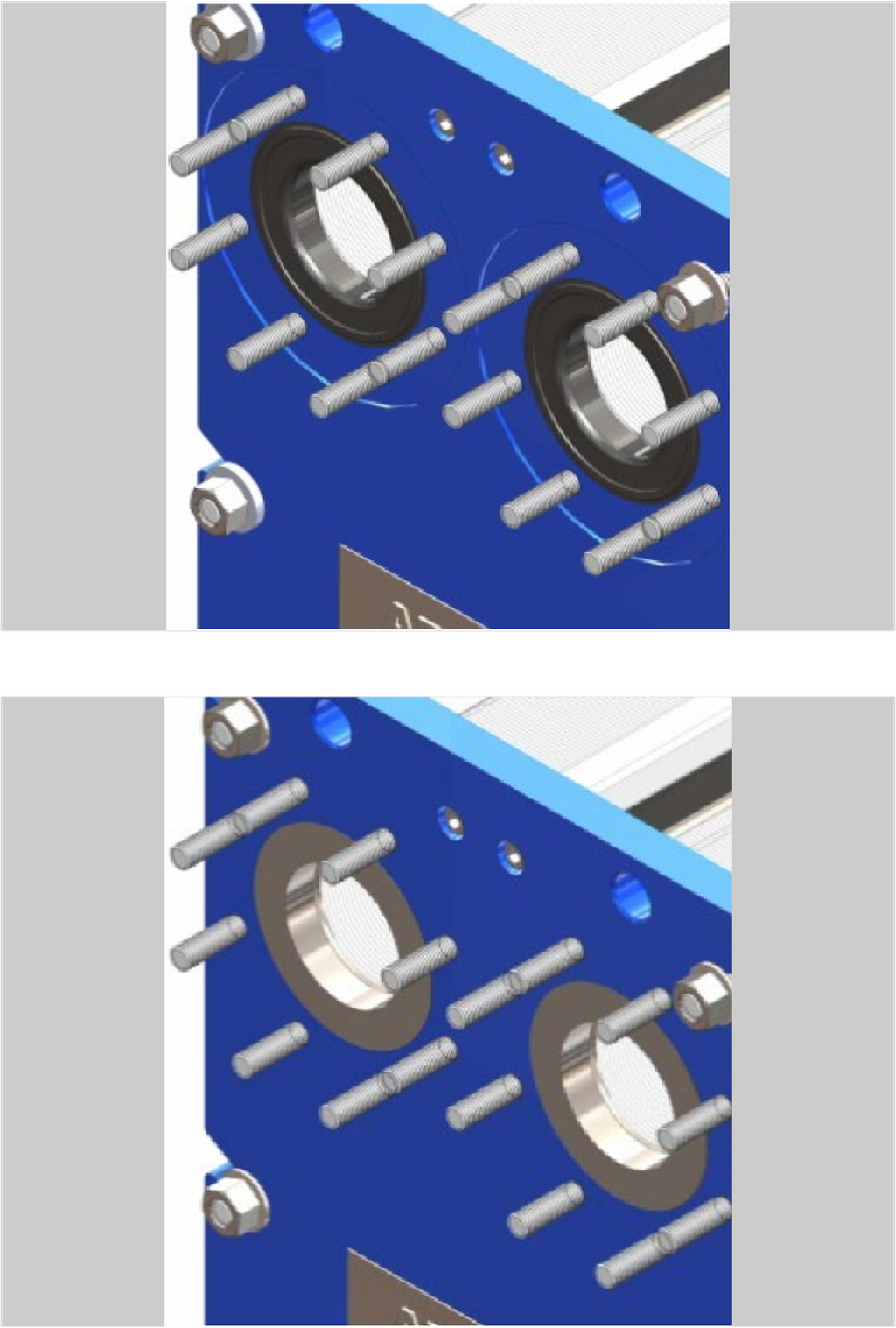

Flanged Port

Special connections can be requested on-demand.

As a manufacturer focused on the customer’s needs, Arsopi Thermal can adapt the heat exchanger connections accordingly to let the customer avoid piping modification and to save costs on the final project.