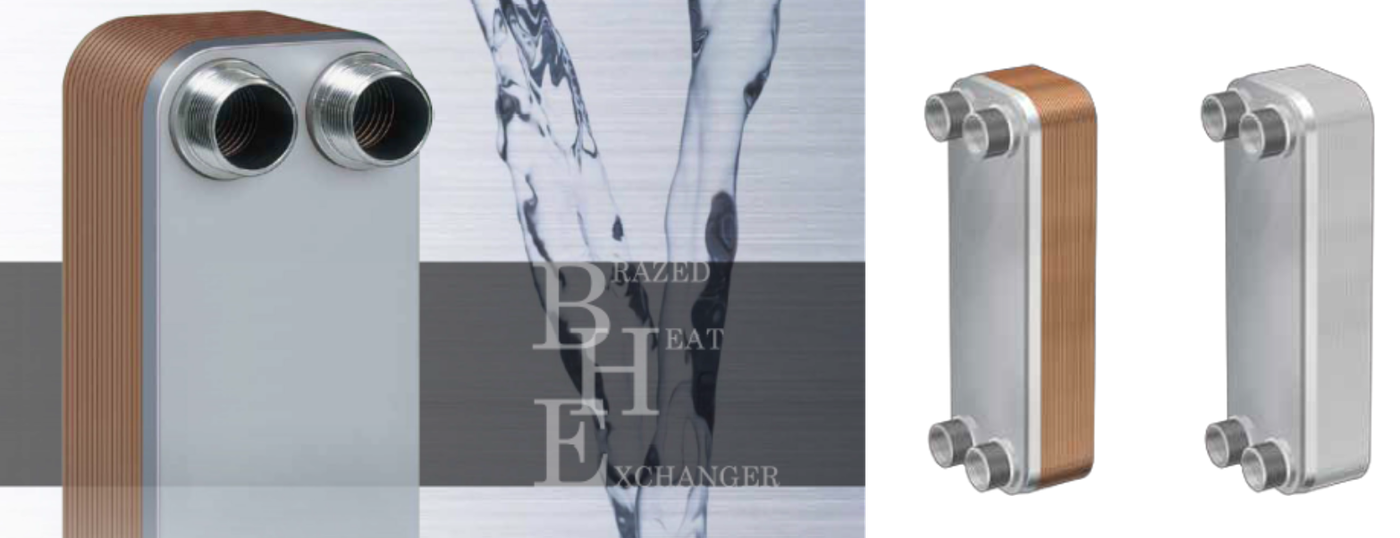

Brazed Heat Exchangers

Main Features

The brazed plate heat exchanger inherits the high performance of the conventional gasket type plate heat exchanger, reduces the number of parts and finishes it in a simpler structure, and by adopting the brazing structure, it is lightweight, compact and durable and enhances sexuality and economy.

The strong sealing performance of the brazed structure also supports heat exchange processes using refrigerants such as ammonia and chlorofluorocarbons.

High performance and allows for a small heat transfer area

Thin heat tranfer plate – Low Heat transfer resistance

Complex flow path – High degree of turbulence

Complete opposing flows – Max use of Terminal temperature gap

Light weight / compact design

Lightweight and compact design with a thin material with a small heat transfer area and a sturdy brazing structure

High pressure and heat resistance, high durability

With brazed structure, it provides a high level of sealing and outstanding heat and pressure resistance.

Design pressure: F.V. to 4.5 MPa

Design temperature: -100°C to 200°C

Excellent economic efficiency

The brazed structure with the minimum number of components is suitable for mass production and is economical.

Applications

- Vaporizers / condensers of refrigerant in compression refrigeration cycles (refrigerators / heat pumps)

- Solution heat exchangers for absorption refrigerators

- Industrial and home water heaters

- Heat recovery heat exchangers for cogeneration systems or gas heat pumps

- Oil coolers for hydraulic equipment

- Heat exchangers for temperature control of various industrial equipment and medical examinations