Technical FAQ

Carry-in & Packing (Shipping)

- I want to know were the end pipes, thermometers, and pressure gauges delivered as options are included.

The end tube is attached to the main body, and the others are packed together with standard accessories.

- I want to know the unloading method and hanging position.

Please check the Instructions and Operations Manual.

- I am planning to export to overseas, but I would like to know if it is related to the trade control ordinance.

Our logistics department will help you with the delivery process according INCOTERMS with all documentation needed. As many possibilities as INCOTERMS regulation for example we can ship it to your place or we can deliver it at our workshop and wait your transport company to pick up the goods, among other possibilities.

Installation / piping

- Do you need space around the heat exchanger?

A maintenance space is required for disassembling the equipment and attaching / detaching the heat transfer plate.

Please check Instructions and Operations Manual procedures.

- I need a thermometer and a pressure gauge together.

Yes, we can arrange it.

We can also provide short plumbing to attach the instrument to your piping.

- Can I turn it sideways?

Some models are compatible, but basically use it in the orientation shown in the assembly drawing.

Please contact Arsopi Thermal for further information.

- What kind of fluid can run through a Plate Heat Exchanger?

Compatible with various types of liquids and gas. It will also depend on the gasket’s and plate’s material.

Including solid-containing fluids / fluids that are dangerous when mixed with utilities.

Also, some PHE’s can be used as gas condensers.For more information, please contact us.

- I want to use seawater, but what should I do with debris in seawater?

Remove debris from the heat exchanger at the previous stage to prevent it from getting inside. We can also propose Inlet Strainers with the heat exchanger.

Sometimes filter is not enough and open for cleaning is needed.

You can contact our Arsopi Thermal Technical Assistance team to help you.

- I want to prevent scattering to the environment because I handle dangerous fluids.

We can propose protective guards (top and sides) of the heat transfer plate to avoid possible accident with this dangerous fluid in direct contact with the operators.

Please contact us for further information.

Frame

- What are A plate and B plate?

There are two types of heat transfer plates: A plate and B plate.

As for the plate, A plate and B plate are alternate sequence.

If the A plate is turned upside down, it becomes the B plate, and if the B plate is turned upside down, it becomes the A plate.

- I don't know where to look for the model / serial number

The model number and 5-digit serial number followed by “-TH” are shown on the name plate attached to the main body. You can also check the model and serial number from the cover of any drawing.

- What is multipass solution?

Normally, the fluid flows through the heat transfer plates from the bottom connection to the top connection (or viceversa) with all connections in the same front frame (1 pass). In case we need to control thermal approach or/and pressure drop, the fluid can flow through the heat transfer plates and more passes are needed than once. The connections now are in different ends, front and rear frame. The plate arrangement is then called multipass solution.

Maintenance and inspection

- I want to know how to clean the heat transfer plate.

Regular maintenance and inspection are recommended for long-term use.

The maintenance / inspection cycle varies depending on application, working conditions, fluids, process requirements, etc.

In the case of a new installation, perform maintenance / inspection once a year as a guide.Depending on the result, set an appropriate interval.

An effective maintenance cleaning method depends on the type of fouling and scaling in the plates.

It may be that it will not be removed by flushing with water and/or cleaning agent.You can ask support from our specialists, the After Sales Team.

Our specialized services and technical expertise are adapted to your heat exchangers and your needs.

- I want to know about slit-in gaskets (no adhesive required).

By providing a notch (slit) on the outer circumference of the plate and setting the protruding part on the plate gasket, the gasket can be attached to the heat transfer plate without adhesive.

In addition, some few heat transfer plates do not have slit-in gaskets, so please contact us for further information.

- I want to know how to distinguish the material of the gasket.

Rubber gaskets have color markings to identify the material.

Please refer to the General Arrangement Drawing for material details, or contact Arsopi Thermal After Sales Team, informing the manufacturing g number and the color code.

- I want to know the quantity of one gasket set required for one heat exchanger (in the case of one pass).

One set of intermediate plate gaskets (number of sheets 1), one set of D gasket and distance piece to be attached to the D plate, and one set of E gasket to be attached to the surface of the E plate (some are unnecessary depending on the model) are required.

For details, please contact our After Sales Team, informing the manufacturing number.

- I want to know how to distinguish the material of the heat transfer plate.

You can always refer to the General Arrangement Drawing. Otherwise, when the equipment is delivered, the heat transfer plate is marked with a lot number that identifies the material.

Please check the lot number and contact our After Sales Team, informing the manufacturing number.

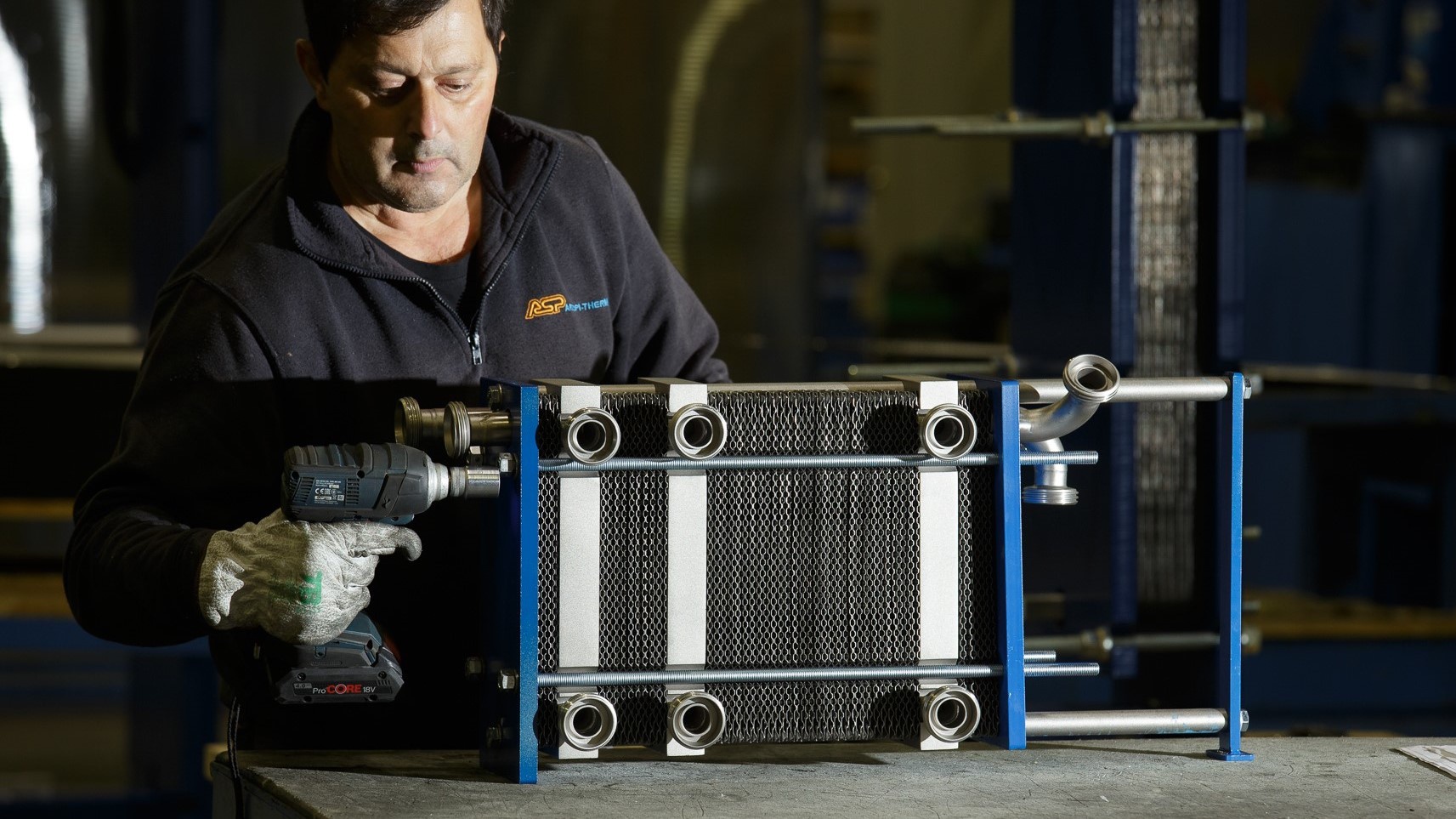

Use cut-resistant gloves when handling not to cut your fingers on the end face of the heat transfer plate.

- I want to know how to manage the tightening of the heat transfer plate.

Plate heat exchangers are controlled by the dimensions between the S frame and the inside of the E frame.

No torque management is required.

Check the tightening dimensions as they are printed on the name plate and General Arrangement Drawing.

- Heat exchanger does not perform as expected.

a) Is the heat transfer plate dirty?

If the heat transfer plate is dirty, the scale attached to the heat transfer surface becomes heat transfer resistance, reduces the capacity of the heat exchanger and increases the pressure drop.

It is necessary to disassemble the equipment once, check the dirt condition, and clean the heat transfer plate. You can ask support to our specialists, our After Sales Team to help you.b) Are the pipes connected as shown in the drawing?

The performance of plate heat exchangers varies depending on how the fluid flows.

Since it is designed including the connection positions of the pipes (fluid inlet and outlet), sufficient heat transfer performance cannot be ensured if the equipment designed for countercurrent is piped in co-current flow. Check the piping position and correct it.

Please contact us if you need to change inlets/outlets in the heat exchanger due to your piping layout disposition.

c) Are the heat transfer plates well mounted into the heat exchanger?

Check the Plate Arrangement Drawing and set the plate in the correct position.

- Liquid leaks from the plate side to the outside.

a) Since the plate gasket is a wear part, it will deteriorate after being used for some time.

Replace the plate gasket.

Rate gasket replacement cycle:

Operating Temperature

Estimated gasket replacement

Hot water above 100 °C 1-3 years Warm water above 30 ° C - 100 ° C 5-7 years Water below 30 ° C 5-10 years b) Are the tightening dimensions within the specified range?

As the rubber gaskets naturally lose their ability to seal the fluids inside the heat exchanger, gradual tightening of the plate pack may be necessary regularly. Tightening of plate heat exchangers is controlled by the tightening dimensions indicated on the name plate between MAX and MIN.

Please observe the instructions in the Instruction and Operating Manual when tightening the plate pack. NEVER tighten to a dimension less the MIN, as it will damage the metallic plates.

In case of doubt, please contact our After Sales Team.

c) Is the thickness and number of heat transfer plates the same as the name plate?

The tightening dimensions of the equipment are determined by the thickness and number of heat transfer plates.

If the thickness / number of heat transfer plates is thinner / less than the design, tightening to the tightening dimensions according to the name plate will loosen the tightening of the entire device and fluid will leak to the outside.Make sure that the plate thickness and number of plates are as stated on the name plate.

d) Is the heat transfer plate correctly organized?

The heat transfer plates are sequenced so that the “A” plate and the “B” plate alternate. If the A / A or B / B sequence continues, the sealing performance will decrease.

Pease refer to the Plate Arrangement Drawing.

e) Is there any foreign material caught in it?

If foreign material such as gravel or dust gets between the gasket and the heat transfer plate during disassembly and assembly, it may cause liquid leakage.

Carefully wipe the sealing surface of the plate gasket with a waste cloth or similar.

- I want to check if the two liquids are mixed.

Use may cause deterioration of the gasket and damage to the plate.

If there is a tendency to mix the two liquids in the piping etc., you can check if the plate is damaged by this method.Method 1: Air test

You can easily check the damage status of the heat transfer plate without disassembling the heat exchanger by pressurizing one side, keeping the other open. If plates are damaged, the pressure will drop.

Method 2: Dye-penetrant inspection of heat transfer plate

Since the method is performed after removing all scaling form the surface of the heat transfer plate, it can be confirmed with higher accuracy.

Ease of maintenance is one of the great advantages of plate heat exchangers. Since it can be disassembled by removing the tightening bolts, customers can replace parts and clean the plate by themselves.

However, if you do the maintenance yourself, the following risks also occur:

– Leftover scale due to incomplete cleaning of heat transfer plate

– Oversight of pinholes due to small corrosion / cracking

– Damage to the heat transfer plate due to excessive tightening

– Incorrect installation of heat transfer plateTry the specializes services of Arsopi Thermal After Sales Team.

- I want to improve the performance of the heat exchanger.

If there is scale buildup in the heat exchanger

The scale may interfere with heat exchange and reduce the performance of the heat exchanger.

Disassemble the device and remove the scale.If there is no scale in the heat exchanger

The performance of plate heat exchangers can be adapted by disassembling the equipment, adding or replacing plates.

Please contact Arsopi Thermal for any advice form one of our specialists.